PCB

PCB

Blog Article

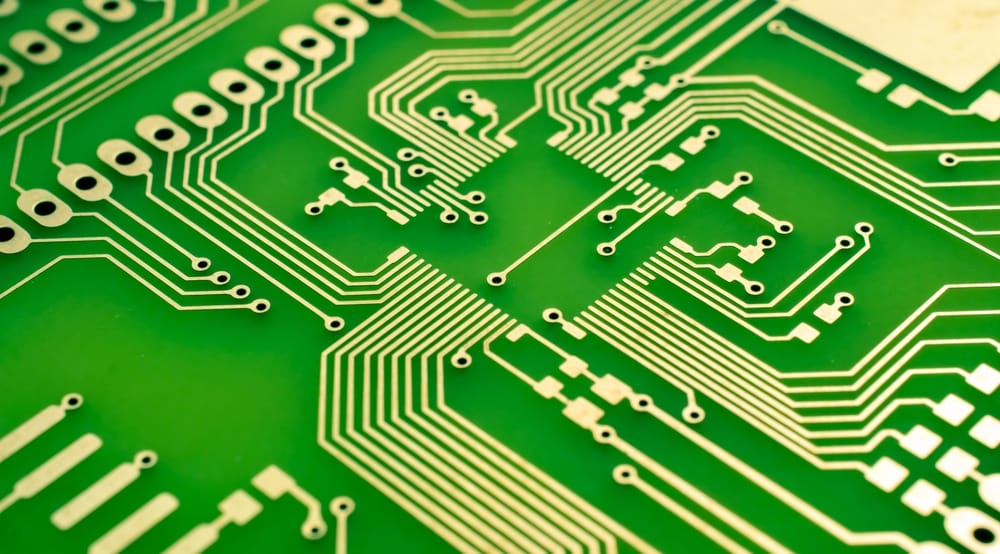

Multilayer Flexible PCBs: Power and Versatility in a Thin Package

Multilayer Flexible PCBs, often referred to as Multilayer Flex Circuits, are a remarkable advancement in the field of electronics and PCB design. These sophisticated PCBs combine the flexibility of traditional Flex PCBs with the capability to integrate multiple layers of circuitry. In this article, we will explore the world of Multilayer Flexible PCBs, their advantages, applications, and considerations in manufacturing. Visit flex circuit board to learn more.

Understanding Multilayer Flexible PCBs

Multilayer Flexible PCBs are designed to provide the best of both worlds: the flexibility of Flex PCBs and the ability to accommodate complex, densely-packed electronic circuits found in modern devices. These PCBs consist of multiple layers of flexible substrate material interconnected by conductive traces. The flexibility of the material allows the PCB to bend and conform to specific shapes, making them ideal for applications where space constraints and form factors are critical.

Advantages of Multilayer Flexible PCBs

1. Space Efficiency:

One of the primary advantages of Multilayer Flexible PCBs is their ability to pack a significant amount of circuitry into a compact form factor. This space efficiency is crucial in applications where miniaturization is essential.

2. Design Freedom:

Multilayer Flexible PCBs offer designers greater freedom in creating complex, three-dimensional shapes. This flexibility is particularly valuable in industries such as aerospace, automotive, and medical devices.

3. Weight Reduction:

Compared to traditional rigid multilayer PCBs, Multilayer Flexible PCBs are significantly lighter. This weight reduction is advantageous in applications where weight constraints impact performance and portability.

4. Enhanced Reliability:

The reduced number of connectors and solder joints in Multilayer Flexible PCBs can lead to improved reliability and signal integrity. This makes them a preferred choice for high-reliability applications.

5. Reduced Assembly Complexity:

Multilayer Flexible PCBs can simplify the assembly process by eliminating the need for connectors, cables, and rigid interconnects, which can be prone to failure and increase assembly complexity.

Applications of Multilayer Flexible PCBs

Multilayer Flexible PCBs find applications in various industries and electronic devices, including:

1. Aerospace and Defense:

In the aerospace and defense sector, Multilayer Flexible PCBs are used in mission-critical applications such as radar systems, communication equipment, and guidance systems.

2. Medical Devices:

The medical industry relies on Multilayer Flexible PCBs for devices like medical imaging equipment, diagnostic devices, and wearable health monitors due to their compact form factor and reliability.

3. Automotive:

In the automotive sector, Multilayer Flexible PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and engine control units, where space and weight considerations are crucial.

4. Consumer Electronics:

Smartphones, tablets, and other portable devices benefit from Multilayer Flexible PCBs, allowing for thinner and more compact designs.

5. Industrial Automation:

Multilayer Flexible PCBs are used in industrial automation for their ability to withstand harsh environmental conditions while providing compact and reliable solutions for control systems.

Manufacturing Considerations for Multilayer Flexible PCBs

Manufacturing Multilayer Flexible PCBs is a complex process that involves precise layer alignment, lamination, and controlled etching. Designers and manufacturers must consider factors such as material selection, layer stackup design, and tolerances to ensure the integrity of the final product. Quality control measures, including electrical testing and visual inspection, are essential to guarantee that the Multilayer Flexible PCB meets the required specifications and reliability standards.

Conclusion

Multilayer Flexible PCBs represent a remarkable advancement in PCB technology, combining the flexibility and space efficiency of Flex PCBs with the ability to integrate multiple layers of circuitry. As electronic devices continue to shrink and become more complex, Multilayer Flexible PCBs will play an increasingly vital role in enabling innovative and compact designs across a wide range of industries. Their unique combination of features makes them a preferred choice for applications where size, weight, and reliability are paramount.

Report this page